Archive for October, 2016

More detail on the pedal-powered apple washer

October 29, 2016Holly’s year 12 report up on Tooling Up

October 25, 2016Holly posted a writeup with more and better photos; check it out at his blog.

Cider year 12: Dry Spell

October 22, 2016

We gathered last weekend with family and friends as we have for 12 years now, to turn over a ton of apples into sweet and traditional cider using muscle power and bicycle-powered equipment. Despite the drought we managed to secure 4 bins of apples (about 2400lb) and pressed them into about 190 gallons of cider. About 70 gallons of this went into carboys; the rest was distributed among the many folks who pitched in.

The pedal-powered cider equipment that we use to make the cider has stabilized over the years; it functions reasonably reliably, and with work obligations and projects in Gorham, we’ve been content to leave good enough alone. One thing that’s helped is the discovery of Fluid Film, a strange cross between WD-40 and axle grease; it smells strange (apparently it’s made out of sheep) but it acts like cosmoline and keeps the sprockets, chains, and bearings from rusting between pressings. The grinder was running hard when I set it up, and I traced the problem to a single bad bearing (we use the cheap 5/8″ pillow blocks that McMaster sells); fortunately it was one of the easier ones to get at and replace.

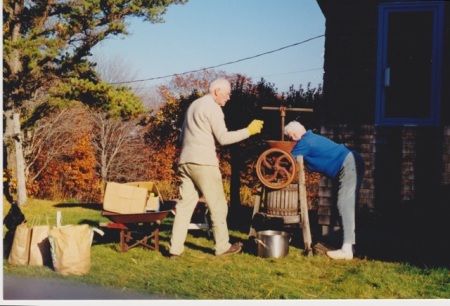

The big addition to the cider equipment this year was a washer/tumbler that we cobbled together this year in response to repeated complaints about the drudgery of hand-washing the apples. Historically we have given each apple a light scrub by hand on its way to the grinder; this removes mud and gives an opportunity to find bad spots and cut them out. I believe this attention to detail is part of what makes our cider so tasty, but it’s a lot of work, and it gets unpleasant especially on a colder day. So the Kaufmans and I hatched a plan for a pedal-powered apple washer. I’ll report the details in a separate post, but despite extreme levels of kludge and haste, it actually worked pretty well. Here’s a photo of the washer in action; there’s video at this link: https://youtu.be/d_HfTvYqEH4

Friday evening folks started to gather in Five Islands by the shore cabin; we ate burritos and continued the tradition of Viking Funeral Ships, then talked around the campfire. Stephen and his crew helped unload the last bin of apples using the four-fall block and tackle in the big barn:

With only 4 bins of apples to process, we could afford a leisurely start; unfortunately the Kaufmans had sick kids and couldn’t make it, but nonetheless Kelsey and Beth pre-made the usual fantastic breakfast burritos enjoyed by the morning crew. Ben and Bodhi used their Odyssey of the Mind skills to put finishing touches on the apple washer, including lining the tube with astroturf and arranging splash guards made of aluminum flashing.

Meanwhile, we threshed the winter wheat grown between two rows of apple trees in the orchard this summer. The first step was to thresh it in a 50-gallon barrel; we tried threshing by hand but the sheaves had gotten disorganized and this proved difficult, so I resorted to attacking it with a string trimmer in the barrel. This worked remarkably well, and deserves further attention to see if it can be made to work for oats, buckwheat, or other stuff that’s hard to hull. We then winnowed over a stack of window-box fans:

This resulted in a fairly clean 16 lb of wheat, which was ground along with dried sweet corn left over from the Stroudwater garden and some ordinary whole-grain corn Holly brought to make the cornbread for dinner, as well as for the crisp. Gene and Kelsey Kaufman had previously built a compact, attractive stand for the grain mill we got last year, with a built-in pedal drive hacked from the bottom bracket of a cheap bike from the dump.

We got rolling around 10AM, and grinding and pressing went smoothly, with nothing more than a few loose bolts and dropped chains requiring attention. Having processed nearly 3 bins we broke for a leisurely lunch, and the heavenly smell of the Nebraska Cream Can Dinner. Ned also made cider donuts, which turned out more like fritters; oddly one of the newcomers had misheard the event they were attending as an apple fritter party, so in the end we managed not to disappoint.

Bottling the 2015 cider got started late, so we only bottled 6 tanks, but it’s not the end of the world to have a few gallons left in kegs for use this fall. After lunch we processed the last few hundred pounds of apples, and cleared out the barn for dinner. Holly and Becky made a delicious pot of chili, hearty cornbread with pedal-ground grain, and massive quantities of delicious apple crisp. Here is the tired couple enjoying the fruits of their labor:

After dinner we lit a fire in the ‘redneck reflector oven’ fashioned from an old heating oil tank, and warmed ourselves with an entire truckload of pallets that Rachel hauled up from Westbrook in her truck. We also lit a section of hollow pine log, a trick learned from arborist Brian Gehan, which burned spectacularly and then settled down into a remarkable ‘demonic esophagus from hell’ – truly an arresting sight:

On Sunday morning we ate blueberry pancakes (wheat, berries, and syrup from the land on Five Islands), continued cleanup, and said goodbye as folks departed for as far away as San Francisco.

One of the highlights of the trip was the reprise of the custom event T-shirts, generously provided by the Jones family in St. Louis, even though a musical performance prevented them from attending as in previous years. The screen retained Jonah and Holly’s acclaimed chainring/apple design, referenced the historic drought, and noted the passing of my grandfather, Bill Herman, who was a big part of my inspiration for growing apples and making cider. Here’s the cleanup crew dressed in cider shirts – we had some printed on undyed fabric and used them in the press, giving them the lovely cider-tanned color we’ve come to love. In another year or two they should take on the hue of Holly’s pants and hat (at left in the photo below), which has proven remarkably colorfast – witnessed by the fact that those are one of the two pairs of pants in Holly’s rotation, thanks to his admirable decision to forswear buying clothes.

As I write these words by the warmth of a low fire, a grateful rain is falling, and the river awoke and rose in the night. Next year’s apple blossoms wait beneath the bark as the leaves yellow and fall. Perhaps the drought will be over soon. Thanks to all who helped to make year 12 a special memory.